Remote-Controlled Overhead Crane and Hoist Safety

Remote-Controlled Overhead Crane and Hoist Safety Guide

In the world of industrial material handling, overhead cranes and hoists play a crucial role in moving heavy loads efficiently and safely. With advancements in technology, many operations are now adopting remote-controlled systems to improve productivity and safety. However, with these advancements come new safety considerations that must be addressed to protect operators, equipment, and facilities.

This comprehensive guide outlines essential safety practices, potential hazards, and preventative measures for using remote-controlled overhead cranes and hoists.

Why Choose Remote-Controlled Overhead Cranes and Hoists?

Remote-controlled systems offer numerous advantages over traditional crane and hoist setups, significantly enhancing both safety and productivity. By allowing operators to control cranes from a safe distance, these systems minimize the risk of accidents caused by proximity to heavy loads or hazardous environments. Additionally, operators can position themselves to have an unobstructed view of the load and surrounding area, reducing blind spots and improving accuracy during operations. From a productivity standpoint, remote-controlled systems streamline workflows by enabling faster and more precise load handling. They also provide operational flexibility, allowing a single operator to manage multiple cranes or hoists seamlessly. This combination of safety and efficiency makes remote-controlled systems an increasingly popular choice in industrial environments.

Enhanced Safety: Operators can control the crane from a safe distance, reducing exposure to hazards.

Improved Visibility: Remote controls often allow operators to position themselves for better visibility of the load and surroundings.

Increased Productivity: Reducing the need for manual operation can lead to faster and more efficient workflows.

Flexibility: Operators can control multiple cranes or hoists from a single device, streamlining operations.

While these benefits are significant, ensuring safety remains a top priority.

Common Hazards in Remote-Controlled Crane Operations

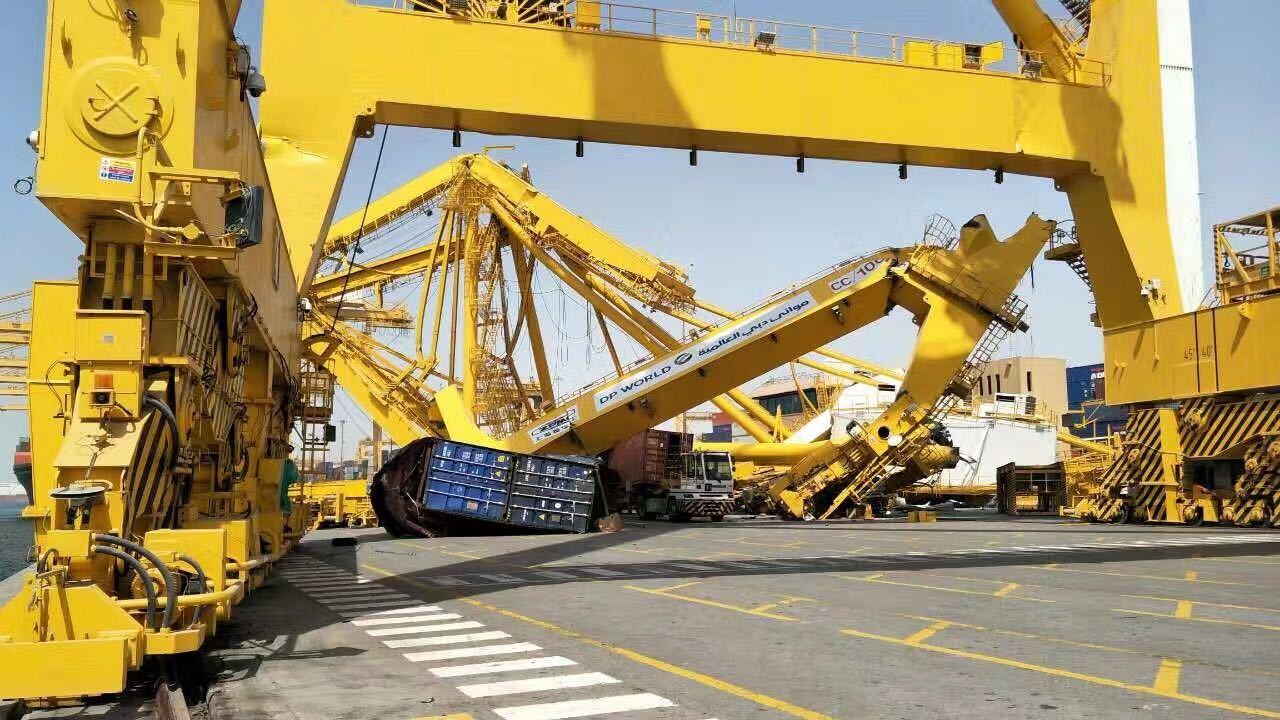

Despite the advantages, remote-controlled crane operations present unique risks, case in point, an incident at the Port of Rotterdam in 2018, where a remotely operated container crane malfunctioned, causing a container to fall and severely injure a nearby worker. Other hazards include:

Poor Visibility: Obstructions or blind spots can make it difficult to monitor the load and surroundings.

Communication Failures: Miscommunication between operators and ground personnel can lead to accidents.

Signal Interference: Wireless signals can be disrupted, causing loss of control.

Mechanical Failures: Equipment malfunctions can lead to dropped loads or uncontrolled movements.

Overloading: Exceeding the crane's load capacity can cause structural failures.

Best Practices for Safe Remote-Controlled Crane Operations

To ensure safe and efficient operations, follow these best practices:

1. Conduct Pre-Operational Inspections

Before using a remote-controlled crane or hoist, inspect the equipment thoroughly:

Check for any visible damage to the crane, hoist, and remote control.

Ensure that all safety features, such as limit switches and emergency stop buttons, are functional.

Verify that the load capacity is clearly marked and not exceeded.

2. Establish Clear Communication Protocols

Effective communication is essential for safe operations:

Use standard hand signals and verbal commands.

Equip ground personnel with radios or communication devices.

Designate a signal person to coordinate movements.

3. Maintain a Clear Operating Area

Ensure that the work area is free of obstacles and unauthorized personnel:

Use barriers and warning signs to mark the operating zone.

Keep pathways clear for safe movement.

Conduct regular housekeeping to remove hazards.

4. Train Operators and Personnel

Proper training is essential for safe crane operations: Hercules Training Academy offers a range of training programs to ensure that operators and personnel are fully equipped to handle remote-controlled and traditional crane systems safely and efficiently. Available certifications and courses include:

Fundamentals of Overhead Cranes: Covering essential topics such as crane components, safe lifting practices, and industry regulations.

Overhead Crane Operator Training: Focusing on practical crane operation, load handling techniques, and troubleshooting for safe and effective operations.

Investing in these training programs ensures that operators are confident in managing complex crane systems while adhering to safety and compliance standards.

Ensure that operators are certified and familiar with remote-controlled systems.

Provide ongoing training to stay updated on safety protocols.

Educate all personnel on emergency procedures.

5. Use Personal Protective Equipment (PPE)

Ensure that all personnel wear appropriate PPE, including:

Hard hats

High-visibility vests

Safety boots

Gloves and eye protection as needed

6. Implement Load Management Strategies

Proper load management is critical:

Ensure loads are balanced and secure.

Use appropriate rigging and slings.

Avoid sudden movements that could destabilize the load.

7. Monitor Signal Interference

Prevent and address signal issues:

Conduct regular checks for sources of interference.

Use frequency management systems to minimize disruptions.

Have a backup control method in place.

8. Emergency Preparedness

Be ready to respond to emergencies:

Test emergency stop functions regularly.

Develop and practice emergency response plans.

Ensure first aid kits and fire extinguishers are readily available.

9. Regular Maintenance and Inspections

Maintain equipment to prevent failures:

Follow manufacturer-recommended maintenance schedules.

Keep detailed records of inspections and repairs.

Address issues promptly to avoid operational risks.

Advanced Safety Features for Remote-Controlled Cranes

Modern remote-controlled crane systems often come equipped with advanced safety features:

Anti-Sway Technology: Reduces load sway during movement.

Collision Avoidance Systems: Prevents contact between cranes and other objects.

Load Monitoring Systems: Tracks and prevents overloading.

Wireless Range Indicators: Alerts operators when they are nearing signal limits.

Emergency Stop Buttons: Allows immediate shutdown in case of danger.

Compliance with Safety Standards

Adhering to industry safety standards is crucial for safe operations. Key standards include:

OSHA (Occupational Safety and Health Administration) regulations

ASME B30.2 standards for overhead and gantry cranes

CMAA (Crane Manufacturers Association of America) guidelines

CSA (Canadian Standards Association) standards for hoists and lifting equipment

Province Specific Regulations

Workplace Safety & Health (WSH) Manitoba: Ensures safe lifting operations and maintenance practices.

Ontario Ministry of Labour, Immigration, Training and Skills Development (MLITSD): Enforces provincial safety regulations related to cranes and hoists.

Alberta Occupational Health and Safety (OHS): Provides guidelines and enforcement for crane operations within Alberta.

British Columbia Occupational Health and Safety (WorkSafeBC): Covers crane and hoist safety regulations specific to British Columbia.

Ensure that your operation complies with these regulations to protect personnel and avoid penalties.

Conclusion

The adoption of remote-controlled overhead cranes and hoists presents exciting opportunities for increased efficiency and enhanced safety in industrial environments. However, these benefits can only be fully realized when safety is prioritized through proper training, adherence to standards, and the implementation of best practices. By investing in safety measures and staying compliant with regulations, companies can protect their personnel, extend the lifespan of their equipment, and maintain smooth operations.

——————————————————————————————————————————————

The Hercules Group of Companies encompasses a wide portfolio of products and services across multiple, diverse companies.