The Importance of Overhead Crane Maintenance: Ensuring Safety, Efficiency, and Compliance

The Importance of Overhead Crane Maintenance: Ensuring Safety, Efficiency, and Compliance

Overhead cranes are the backbone of many industries, providing essential lifting solutions in manufacturing, construction, warehousing, and logistics. While these heavy-duty machines enhance efficiency and productivity, they also pose significant risks if not properly maintained. Regular crane maintenance is critical to ensuring worker safety, prolonging equipment life, and complying with industry regulations.

In this blog, we’ll explore the importance of overhead crane maintenance, key maintenance practices, Canadian regulations, and how Hercules Crane & Lifting Supplies can help keep your operations running smoothly.

Why Regular Overhead Crane Maintenance is Essential

1. Safety First

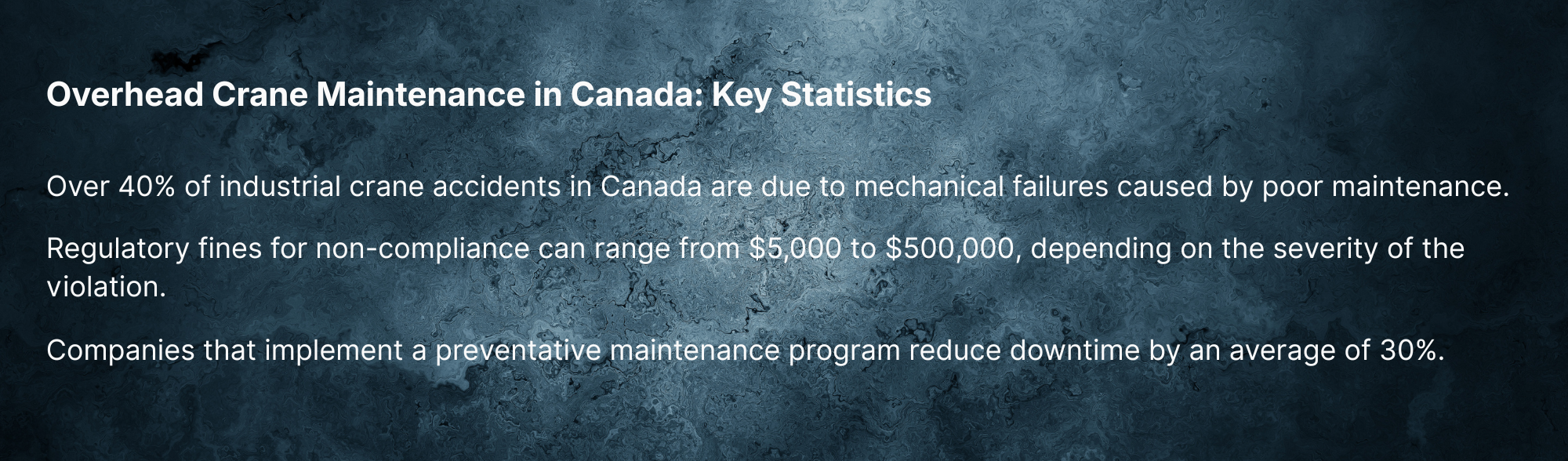

Overhead cranes operate under extreme loads and conditions, making safety the top priority. A poorly maintained crane can lead to mechanical failures, dropped loads, or catastrophic accidents, endangering workers and causing severe damage to facilities.

Key Safety Risks of Poor Maintenance:

Regular inspections and maintenance mitigate these risks, ensuring the crane operates safely and efficiently.

2. Regulatory Compliance

In Canada, overhead crane inspections and maintenance are governed by occupational health and safety (OHS) regulations. Compliance with these regulations helps companies avoid hefty fines, legal liabilities, and workplace shutdowns.

Canadian Regulations & Standards:

CSA B167-16: Safety Standard for Overhead Cranes

OSHA Canada Regulations

Provincial Safety Codes (e.g., Ontario’s Occupational Health and Safety Act)

Manufacturers’ recommended maintenance schedules

Failure to comply with these standards can result in severe consequences, including penalties and operational restrictions.

3. Preventing Costly Downtime

Equipment breakdowns can lead to unplanned downtime, disrupting production schedules and resulting in financial losses. Preventative maintenance reduces the likelihood of unexpected failures, allowing businesses to maintain consistent operations and meet deadlines.

4. Extending Equipment Lifespan

Routine maintenance extends the service life of overhead cranes, protecting your investment and reducing long-term replacement costs. By addressing minor issues before they escalate, companies can maximize their crane’s operational lifespan and maintain peak efficiency.

5. Enhancing Performance and Efficiency

A well-maintained crane operates more smoothly, reducing wear on components and improving lifting precision. This leads to increased productivity, fewer disruptions, and safer operations.

Key Maintenance Practices for Overhead Cranes

To ensure optimal performance, overhead cranes require routine inspections and maintenance. Here are some critical maintenance practices:

1. Daily Inspections

Before each shift, operators should perform a visual inspection, checking for:

Wire rope integrity

Hook deformations

Proper brake function

Signs of wear on moving parts

Oil leaks or abnormal noises

2. Scheduled Preventative Maintenance

Preventative maintenance should follow manufacturer guidelines and regulatory requirements. This includes:

Lubricating moving parts

Checking electrical components

Inspecting load chains and slings

Replacing worn-out parts

3. Annual Load Testing

Load testing ensures the crane can handle its rated capacity safely. It involves lifting a test load under controlled conditions to verify the crane's structural integrity and functionality.

4. Professional Inspections and Certification

Certified technicians should conduct thorough inspections at least once a year. These professionals have the expertise to identify hidden issues and recommend corrective actions.

How Hercules Crane & Lifting Supplies Can Help

At Hercules Crane & Lifting Supplies, we understand the critical role of overhead cranes in your operations. Our expert team provides comprehensive crane maintenance, inspections, and repair services to keep your equipment running efficiently and safely.

Our Services Include:

Preventative maintenance programs

Load testing and certifications

Emergency repairs and troubleshooting

Component replacement (wire ropes, hoists, motors, etc.)

Compliance audits and safety inspections

Why Choose Hercules?

✅ LEEA Certified technicians with years of experience

✅ Compliance with CSA and OSHA standards

✅ Quick response times for urgent repairs

✅ Customized maintenance plans for your business

📞 Call us now 1 (877) 461-4876 to get a free consultation and keep your lifting operations running safely and efficiently.

——————————————————————————————————————————————

The Hercules Group of Companies encompasses a wide portfolio of products and services across multiple, diverse companies.